Circular fashion for all

We enable large scale sustainable change in fashion through business value and inspiration.

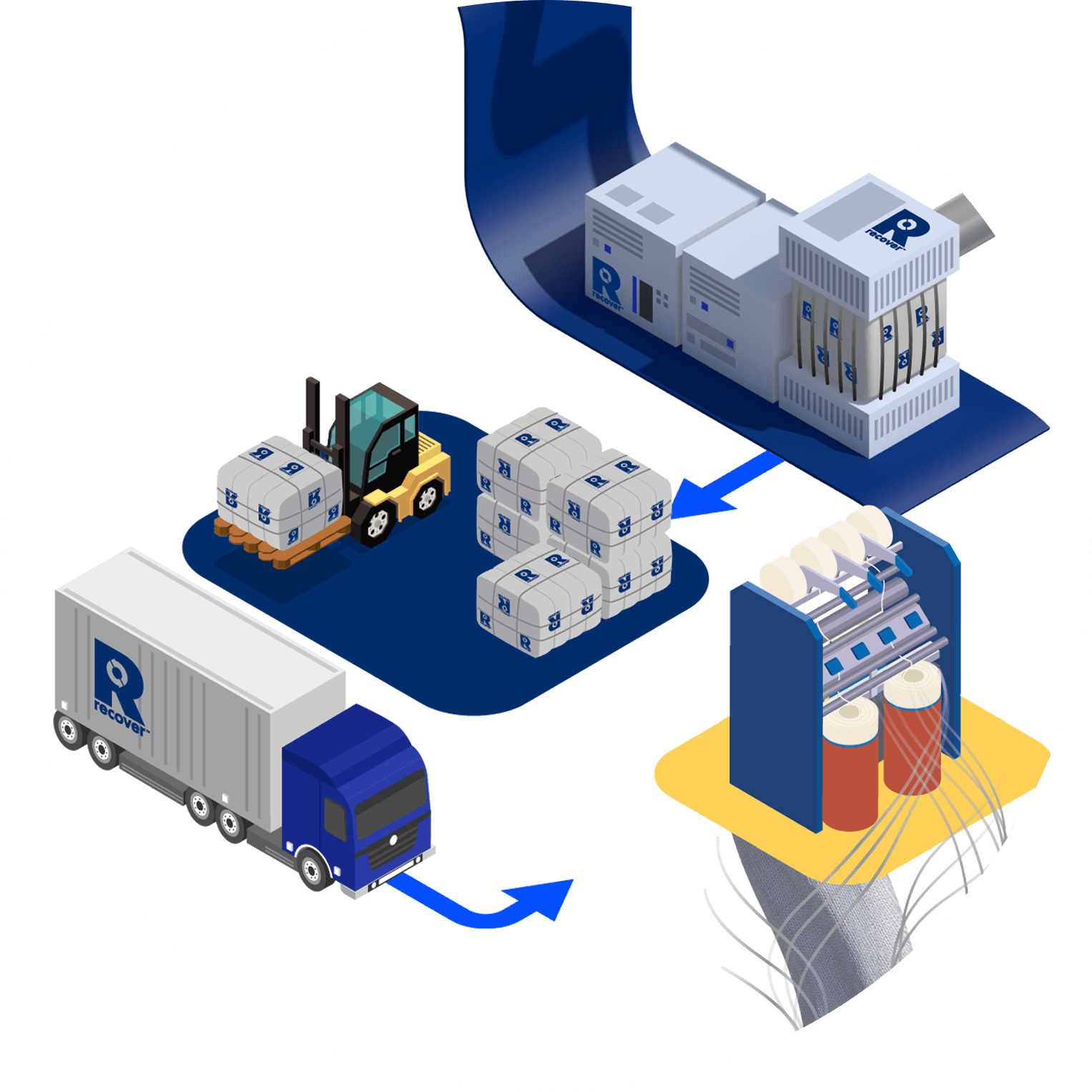

Our process

Textile waste is our raw material, and we use it to create high-quality recycled cotton fiber.

Recover™ turns textile waste from post-industrial and pre- and post-consumer origins into valuable, high-quality recycled cotton fiber and fiber blends. We work together with our strategic partners to integrate our process into the supply chain, providing a closed-loop end-to-end solution.

- Cutting

- Treatment

- Shredding

- Packing

Our products

Shredded fibers

Recover™ offers low-impact, high-quality recycled cotton fiber and fiber blends for all types of fashion, accessory and home textile products.

Blended fibers

Recover™ made from our proprietary FiberSync Technology. 100% recycled blend of color-matched Recover™ recycled cotton fiber and recycled polyester. Ready to spin, no overdyeing required.

Recover™ Fabrics & Blanks

Recover™ Fabrics, from everyday essentials to high-end textiles, and Recover™ Blanks, our ready-to-wear collection of sustainable, unbranded basics.

Our latest news

Tracing Textile Waste with the Reclaimed Material Declaration Form (RMDF)