Circular Products

Recover™ measures the impact of its products and processes at each point in our value chain and continuously works to further reduce the footprint of its activities and products.

Not only do we aim to create products that are aligned with circular principles, we also promote circular design with our supply chain and brand partners. All Recover™ products are traceable, safe, and third-party certified.

2030 Objectives:

- Recover™ is aligned with Science Based targets and our products are made with minimal environmental impact.

- Recover™ is a zero-waste company.

- Recover™ products and practices are aligned with a circular textiles system.

Objective: Recover™ is aligned with Science Based targets and our products are made with minimal environmental impact.

To achieve this objective, the Recover™ team has been working on the following initiatives:

Implement a Life-Cycle Assessment (LCA) of our products across all locations.

A Life-Cycle Assessment is a scientific method used to measure the environmental footprint of a product. The goal of an LCA is not only to measure and improve, but to support customers to make informed decisions when buying products. We are implementing an LCA across all our locations, with the first one being conducted in 2022 in Spain, verified by Ecoreview. As LCAs require at least 6 months of stable data tracking, the LCAs for Pakistan and Bangladesh hubs are planned for 2024. We also commissioned a study to compare the environmental impact of our recycled fibers against virgin and organic alternatives.

Calculate our consumption and GHG emissions.

To further reduce our impact, we are tracking our energy and water consumption across our Spanish and Bangladeshi hubs. We also conducted an energy audit in Spain with INYCOM ENERGY, identifying efficiency improvements. Recover™ uses minimal water, we hence didn't set any reduction target for that category. We are also measuring our Scope 1, 2 and (since 2023) our Scope 3 GHG emissions - with the help of Watershed - which allows us to have a detailed carbon measurement, for ourselves and our suppliers, and set the basis for a decarbonization plan.

Set and commit to a decarbonization plan.

We are committed to setting Science-Aligned Targets (SATs) as required by Cascale in 2023 and we signed the SAT Commitment Letter in November 2023. Due to ongoing construction at our Bangladeshi hub, Recover’s GHG emissions baseline will be established in 2024, with reduction targets set for 2025. We are dedicated to reducing GHG emissions in line with the latest climate science.

Objective: Recover™ is a zero-waste company.

We aim to become a zero-waste company, minimizing the generation of waste and maximizing the recovery of waste produced through our own operations. To achieve this objective, we have implemented the following initiatives:

Setting a Waste Management Policy.

In 2023, the Waste Management Policy was successfully approved by the CEO and published on our website. To become a zero-waste company it is important to constantly consider our waste management practices and implement good waste management practices across the entire organization by establishing the hierarchy of wastes: Prevention > Re-use > Recycling > Recovery > Disposal

Implementing a waste segregation system.

We implement a comprehensive waste segregation system at all our facilities, and we are committed to regularly reviewing and improving our waste management practices and identifying opportunities for optimization and innovation, respecting the hierarchy of wastes. In 2023, we achieved significant improvements: 64% of the waste generated during our own production processes was recycled (+31pts VS previous year) 32% was used for energy revalorization (-25pts VS previous year) and 4% ended up in landfill (-6pts VS previous year)

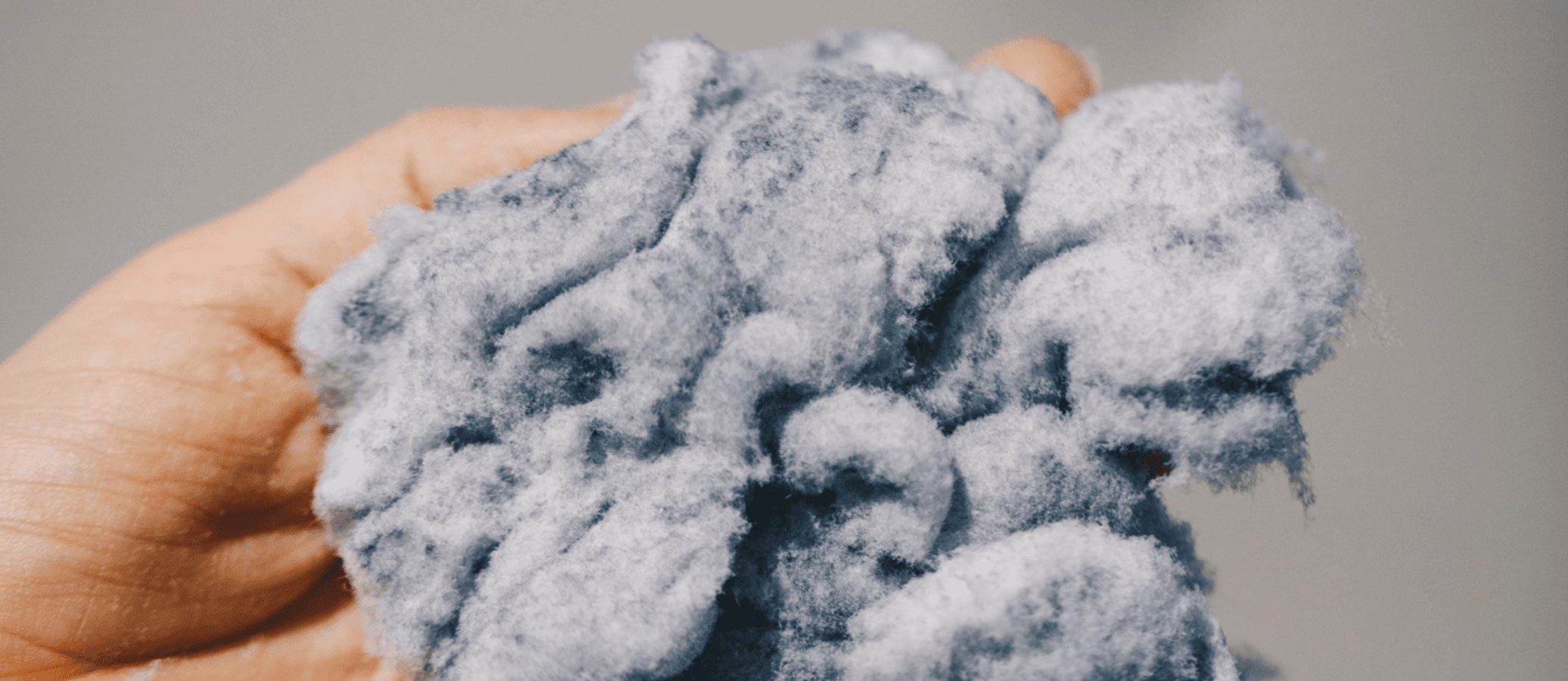

Developing applications for our by-product - RParticule.

Our by-product has been named "RParticle", and is by far the highest volume by-product of our fiber production. These are small fibers, generally smaller than 4 mm, which are absorbed by the extraction system across the entire production process. During 2023, Recover™ was focused on consolidating recycling options for RParticle, as we are conscious about its potential added value for different industries. We partnered with universities and research institutes to test and develop the potential high value options for RParticle, with several possible applications and ongoing projects already.

Objective: Recover™ products and practices are aligned with a circular textiles system.

Recover™ has circularity at its core. We are very active in supporting circular design practices where possible.

Creating circular fashion for the industry.

One of the features that makes Recover™ fiber unique is that our tech support team works closely with spinners and weavers to optimize the quality of the yarn and fabric further down the supply chain and drives the scaling of circular fashion. As of 2023, 138 yarn developments and 43 fabrics developments have been approved. For 2024, we have more than 233 yarn developments and 394 fabrics developments projects in the pipeline. Furthermore, circularity is at our core. 98.58% of the purchased materials in weight during 2023 are textile waste or recycled materials (corresponding to our purchases for our hubs in Spain and Bangladesh).

Leading the way towards scaling post-consumer waste recycling.

As a high-value, textile-to-textile recycler, Recover™ has a key role to play in the transition to a circular fashion system. Recycling of post-consumer textiles is considered by many industry leaders as the “holy grail”. At Recover™, we face a challenge in securing large volumes of suitable post-consumer feedstock for our process. The existing textile collector/sorter business models are tailored to sorting for re-use and downcycling markets. However, Recover™ is committed to being an agent of change in this area, not only by scaling its own recycling of post-consumer textiles but also by being part of key industry projects like Accelerating Circularity Project and the ReHubs initiative that bring together crucial stakeholders

Enabling Circular Design.

Not only do we aim to create products that are aligned with circular principles, but we also promote circular design practices with our supply chain and brand partners. In 2023, we came together with YOOX NET-A-PORTER, and The Prince’s Foundation to support The Modern Artisan. As an active member of the Textiles 2030 initiative, Recover™ also participated in the Design for Circularity working group, working alongside other businesses and industry leaders to align on good practice design principles.

Read more on what we achieved in our Circular Products sustainability pillar in our Sustainability Report 2023.