Understanding the pitfalls of unintentional greenwashing.

Site map

Global Recycled Standard (GRS) is an international certification developed by Textile Exchange; a non-profit organization focused on promoting sustainability in the textile industry. GRS is a voluntary standard with the goal of increasing the use of recycled materials in products while reducing or eliminating the harm caused by their production. It includes standards for fair labor practices, worker safety, and limits the use of harmful chemicals in production. To obtain the GRS, companies must undergo third-party accreditation by a certification body.

Products must include a minimum of 20% recycled materials to obtain the Global Recycled Standard (GRS), although at least 50% is needed for the product to be labeled with the GRS logo.

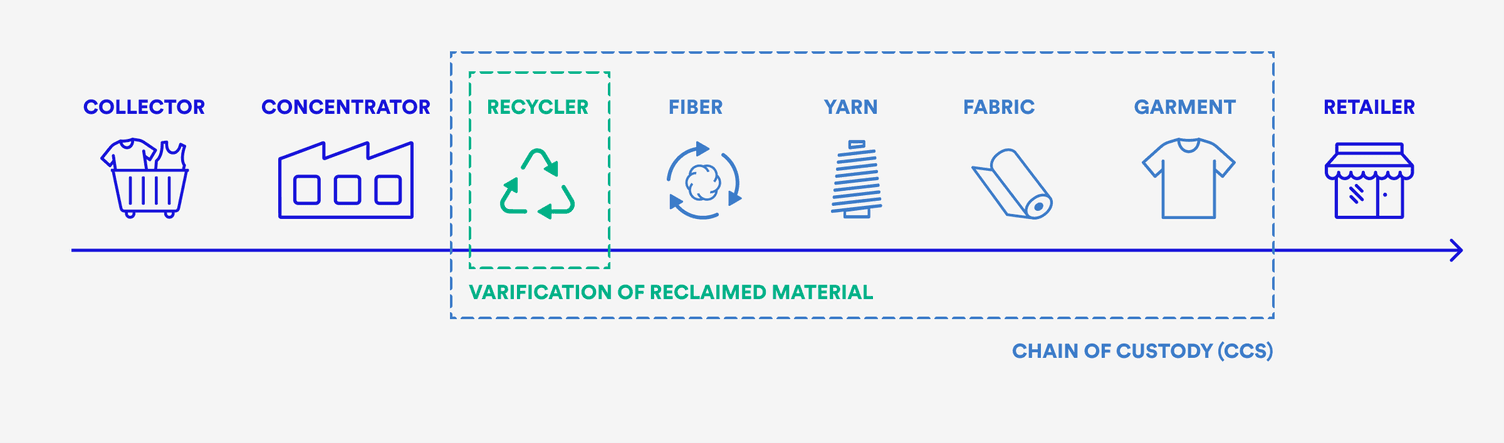

GRS is defined as a full-product standard, meaning it makes sure the recycled content is maintained throughout the chain of custody – from feedstock to final product. Each stage of production along the supply chain must be certified, beginning at the recycling stage and ending in the final business-to-business (B2B) transaction. If at any stage along the way there is no GRS certification, the final product cannot be certified.

It is extremely important that Recover™ is GRS certified because, as a recycler, we are at the very beginning of the chain of custody. This way, the brands and supply chain partners that collaborate with us can produce GRS certified products and obtain certification as well.

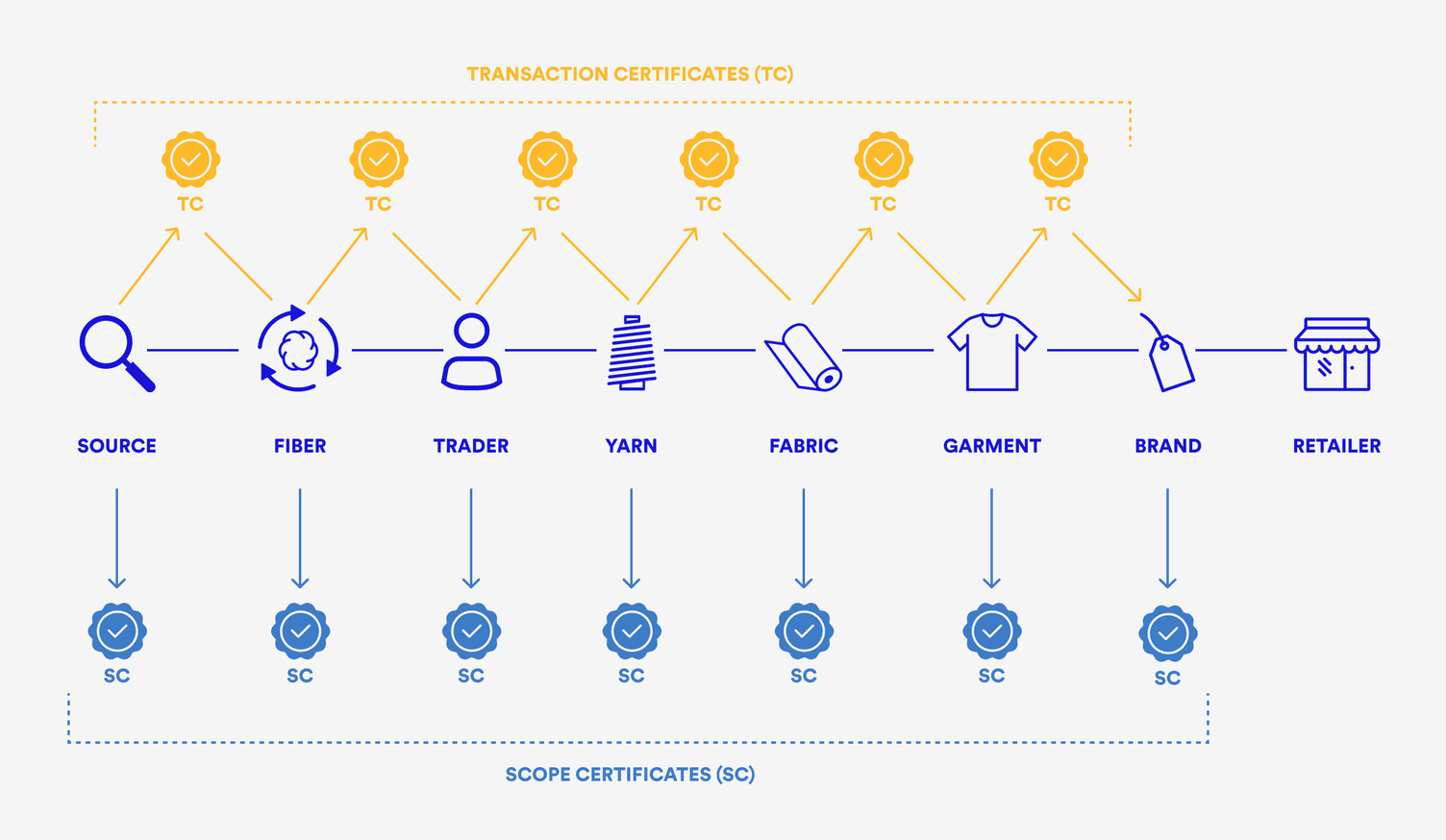

Global Recycling Content certifications are closely connected with Transaction Certificates (TCs) and Scope Certificates (SCs).

To summarize, a TC is the record that guarantees the transaction is GRS certified, while a SC is the document that certifies the company, as illustrated below:

Both TCs and SCs are especially important to ensure the entire chain of custody is certified. Each player in the value chain needs its own SC, obtained by audits, and each time they send materials or products, it is mandatory to issue a TC specifying all the information about the shipment, including composition and weight. The delay to issue a TC is agreed by the buyer and the seller with a maximum of 90 days.

Incorporating recycled materials into production processes offers extensive environmental benefits, from conserving resources and reducing energy consumption to minimizing waste and pollution. These advantages not only help in mitigating climate change but also support the sustainable development goals by promoting more responsible and efficient use of resources.

For a product to be GRS certified, it must have at least 20% recycled material, but what constitutes as recycled materials? According to the GRS, recycled materials are broken up into pre-consumer recycled materials and post-consumer recycled materials.

Pre-consumer recycled materials are diverted from the waste stream during a manufacturing process. These materials have not reached the end consumer and are usually scraps or by-products from production processes.

Post-consumer recycled materials have been used and discarded by consumers, then collected, cleaned, and processed to be reused in new products. These are items that have completed their life cycle as a consumer item and have been diverted from waste destined for disposal.

The GRS certification process is designed to ensure that products have verified recycled content and are produced in a socially and environmentally responsible manner. The process involves several steps to verify the authenticity of recycled materials and ensure compliance with the standard’s requirements.

Companies interested in obtaining GRS certification must first ensure that their suppliers are also GRS-certified. If they are not certified, as GRS certification depends on chain of custody certification, it is not possible to become certified.

Once a company is certain that their suppliers are already GRS certified, they can contact an accredited certification body. These organizations handle conducting audits and issuing certifications.

Prior to the audit, the company should conduct an internal review of its processes to ensure they meet GRS standards. This includes verifying the source and authenticity of recycled materials and assessing social and environmental practices. During the review, companies should gather recycled content records, chain of custody information, environmental, social, and chemical compliance records, and implement a Quality Management System.

Once all necessary information is gathered, the certification body will schedule an on-site audit. This visit is crucial to verify the accuracy of the documentation provided and the implementation of GRS requirements. During the audit, auditors will inspect facilities, review records, and interview employees.

If the company meets all GRS requirements, the certification body will issue a GRS certificate. This certificate is valid for one year and can be renewed annually through a recertification process.

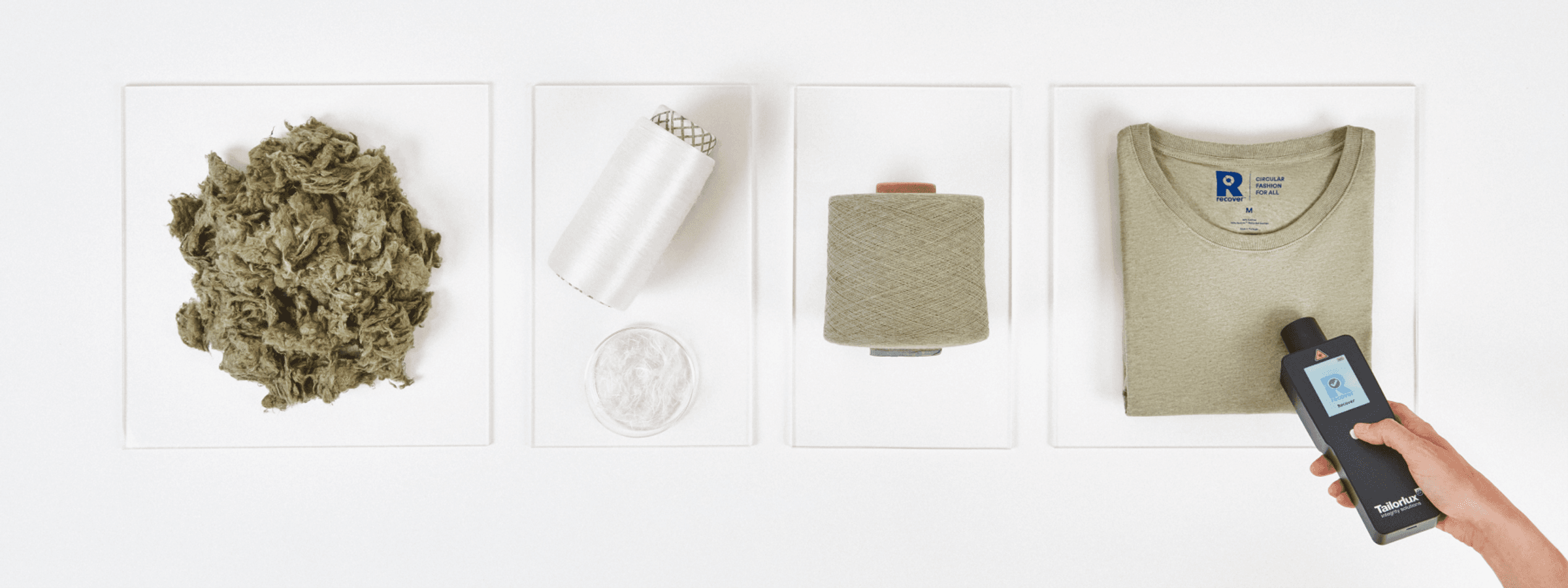

Not only is Recover™ GRS certified, all Recover™ fiber can be embedded with a physical tracer. This allows us to accurately track and verify that the fiber is indeed Recover™ fiber, not an imitation. By enabling direct tracking of materials throughout the supply chain, we can provide real-time data and significantly reduce the risk of fraud. Our long-term sustainability vision on recycled fibers includes transparency and traceability. Traceability is crucial for the GRS, and our development of a physical tracer enhances the precision and reliability of material tracking, ensuring the authenticity of recycled materials. Implementing a tracer in all Recover™ fiber opens many possibilities, as it enables us to watch the fiber's journey throughout its entire product life cycle.

https://textileexchange.org/app/uploads/2021/02/GRS-v4.2-Implementation-Manual.pdf

https://textileexchange.org/recycled-claim-global-recycled-standard/