Here's what you need to know about the new EU strategy for textiles.

Site map

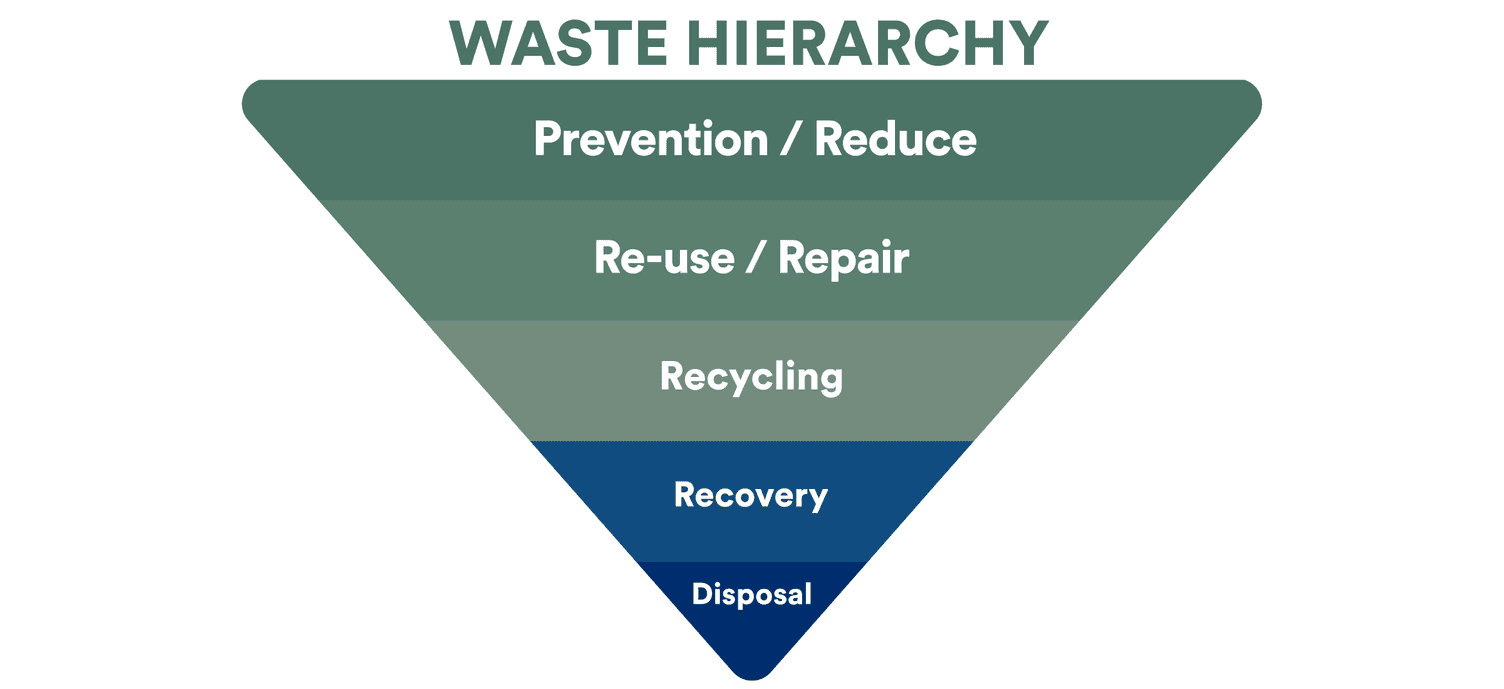

The Waste Hierarchy model is a tool developed by the Waste Framework Directive to facilitate and optimize waste management. It provides an order of priorities for waste management, ranked in terms of environmental impact. This guide explores the waste hierarchy model and its different levels in depth.

The waste management hierarchy is a conceptual model which helps both individuals and organizations take better-informed waste management decisions and maximize the planet’s resources.

The model covers five different waste management decisions including, ranked from best for the environment to worst: waste prevention, re-use, recycling, recovery and disposal. Usually depicted visually as a diagram of a five-tier pyramid, the model guides people on how to prioritize their waste management.

It was created around the Waste Framework Directive - first introduced by the European Union in 1975 and later reworked in 2008. The Directive sets out guidelines that countries must comply with in order to protect environmental and human health through the reduction of adverse effects of waste generation and management. In 2023, another revision was proposed with a specific focus on textile waste to create more circular and sustainable management.

The waste hierarchy is made up of 5 different waste management processes, ranked from most preferable to least preferable based on their environmental impact. There are multiple variations of the diagram, many of which are based on the 4 “R”s; Reduce, Reuse, Recycle and Recover. Repair is another step that often appears within waste hierarchy charts before recycling; however, in this diagram we recognize repair as an aspect of “re-use”.

Top priority should always be given to avoiding or reducing waste in the first place by reducing the use of raw materials. Companies can do this by minimizing production to what is absolutely necessary. Many brands are already opting for this model, choosing to offer manufacturing on-demand. 3D printing also reduces waste as it allows textile companies to reuse excess or failed prints and work them back into the production process as usable resins or filaments, reducing the need to input new materials. Consumers looking to prevent waste may choose to be more mindful about what they buy - opting for long-lasting pieces to wear over the years.

Other ideas of preventing unnecessary resource consumption could include:

Reducing waste at the source can result in reduced greenhouse gas emissions and pollution, natural resource and energy conservation and cost-saving for consumers and businesses [1].

This process involves reusing materials in their original form, by someone else or as part of another process. A large part of reuse is also repairing items so that they can be used again, rather than throwing them away. These repaired items can then be sold or donated to be used again. As a result, reuse allows items to remain productive and negates the need for waste or new materials. An added benefit of this is that it saves money as it avoids spending on new goods.

Reuse is already on the agenda for many fashion companies. Plenty of brands have an outlet section where they sell unsold items at a lower price to encourage people to buy them. Some companies, especially luxury fashion brands, have developed collections using excess fabrics from manufacturing processes to avoid disposal.

Furthermore, many brands are encouraging clothing repair or tailoring for longer wear. This is also supported by upcoming legislation across the world: France recently launched a repair scheme to encourage people to mend old clothes and shoes rather than throwing them away. The French government pledged 154 million euros ($168 million) to the initiative, which reimburses shoppers up to 25 euros ($27.20) for every garment they have repaired.

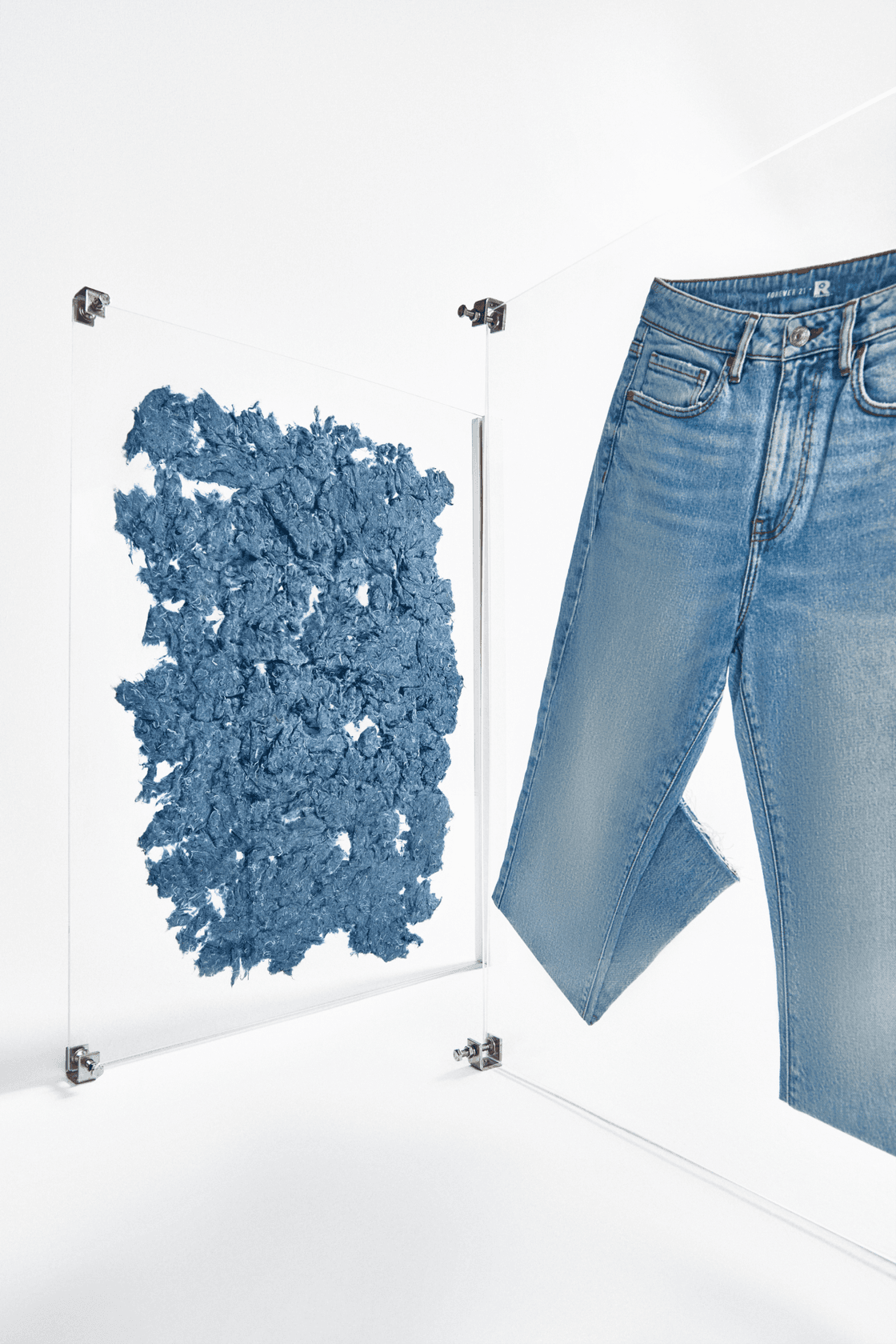

This refers to any operation which involves reprocessing waste materials into new products or materials. It falls as the third level of the waste hierarchy because it requires extra energy and resources. However, whether part of a wider recycling program or at an individual level, recycling can save materials that would otherwise be sent to landfills.

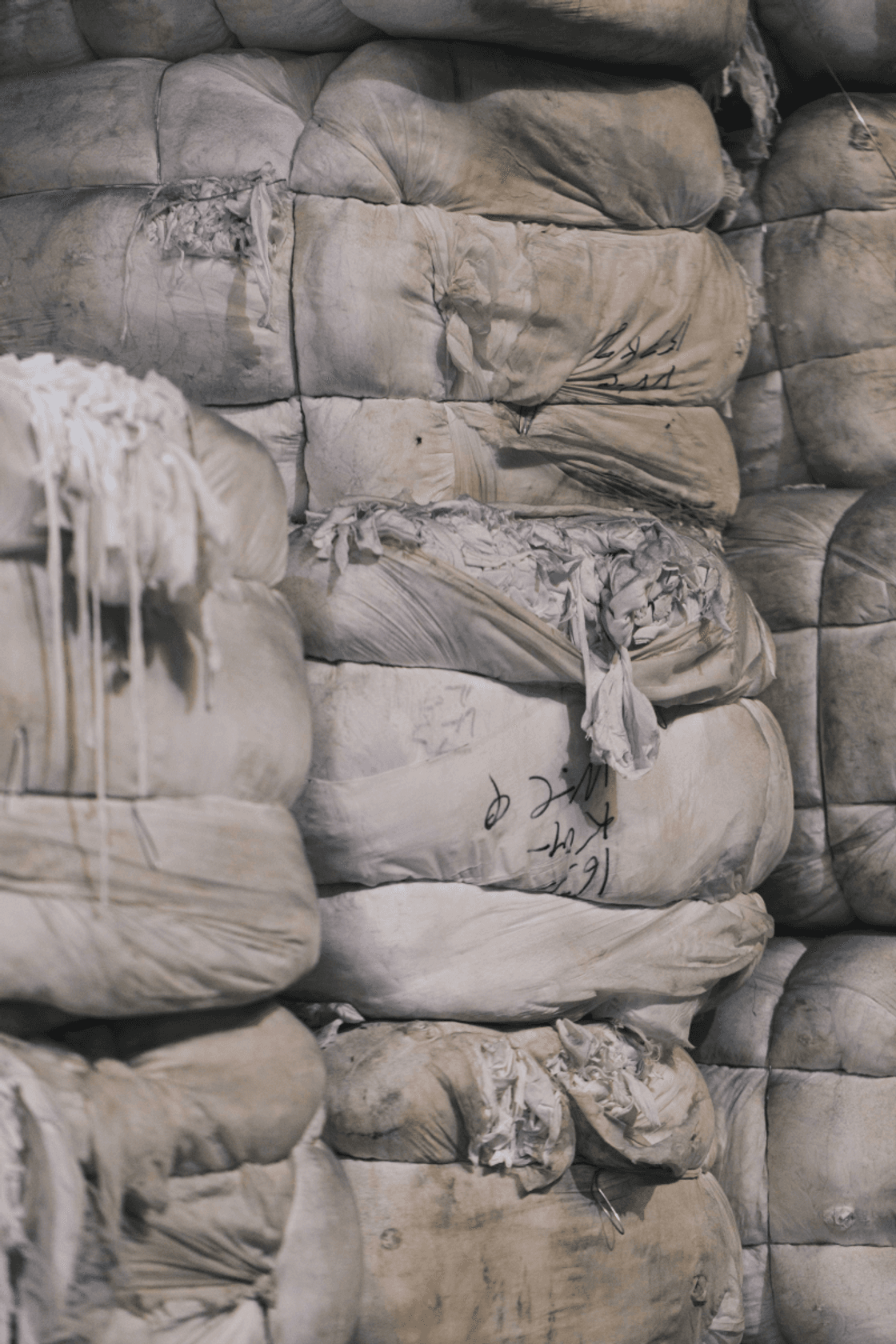

It is estimated that each year, 92 million tons of textile waste is produced globally [2]. Recycling, especially that of clothes and textiles, can create significant environmental savings when compared with conventional alternatives as it avoids the environmental cost of producing a virgin item.

At Recover™, we fall into this category of the Waste Hierarchy. We transform textile waste into recycled cotton fibers through a mechanical recycling process that uses low water and energy, and no chemicals. In 2023, we achieved the following environmental savings, when compared to conventional alternatives [3].

One of the main advantages of the Recover™ process is that we maintain the value of the input. We recycle textile-to-textile, and our recycled cotton can be used in a wide array of products, including denim, t-shirts, tops, sweatshirts, home textiles, accessories, and more. This differs from other mechanical recyclers, which are often associated with downcycling during the recycling process. In downcycling, the recycled output is used for lower-value applications, such as insulation or in the automotive industry.

Where recycling cannot be carried out, energy can be recovered from the material through processes like anaerobic digestion, incineration, gasification, landfill gas recovery or pyrolization. Once recovered, the energy can be fed back into the economy or the electricity grid.

While this should be a last resort for textile sorters and collectors, it is often used as a main option for the fashion industry. There is plenty of post-consumer textile waste received which is perfectly fine for resale, reuse or recycling but in many cases, it is sent directly to be incinerated rather than looking for waste management alternatives.

Finally, the waste hierarchy suggests that only when all other options have failed should disposal be the solution. This is an unsustainable solution as it involves sending materials to landfills or being incinerated without energy being recovered. As a result, there are mountains of textile waste across the world releasing toxins and greenhouse gases which negatively impact the health of humans, wildlife and the environment.

Sadly, this step of the waste hierarchy is one of the predominant in our world, this is known as the textile waste crisis and it is accelerating rapidly, with the apparel industry’s global emissions set to double by 2030 if preventative action is not taken [4]. In the United States alone, landfills received 11.3 million tons of textiles in 2018, that’s equivalent to 85% of all textiles – and up to 37 kilogram per person year – a very alarming statistic [5]. Yet, there are so many steps that both consumers and brands can take before arriving at this level of the waste hierarchy.

As a leading textile recycler, our mission at Recover™ is to minimize the reliance on the last step of the Waste Hierarchy - Disposal.

Partnering with Recover™ means becoming a frontrunner in sustainability and circularity in the textiles industry. Not only do we help enhance textile recycling within your business but, with in-house experts in sustainability and innovation, we can help you educate your consumers or internal stakeholders on circularity, waste prevention and sustainable practices to promote circularity at a wider level.

Together, we can work to promote better textile waste management and minimize the footprint of the fashion industry.

[1] Environmental Protection Agency (EPA), (2024), Sustainable Materials Management: Non-Hazardous Materials and Waste Management Hierarchy.

[2] Kerr J, Landry J (2017) Pulse of the fashion industry. Global Fashion Agenda, The Boston Consulting Group, Boston.

[3] Recover™ (2024), Sustainability Report 2023.

[4] Quantis (2018), MEASURING FASHION: Environmental Impact of the Global Apparel and Footwear Industries Study (page 5).

[5] United States Environmental Protection Agency (2023), Textiles: Material-Specific Data. Equivalences made by Earth.org in their article “10 concerning fast fashion waste statistics” (2023).