What is Recycled Cotton and Why Does it Matter?

Site map

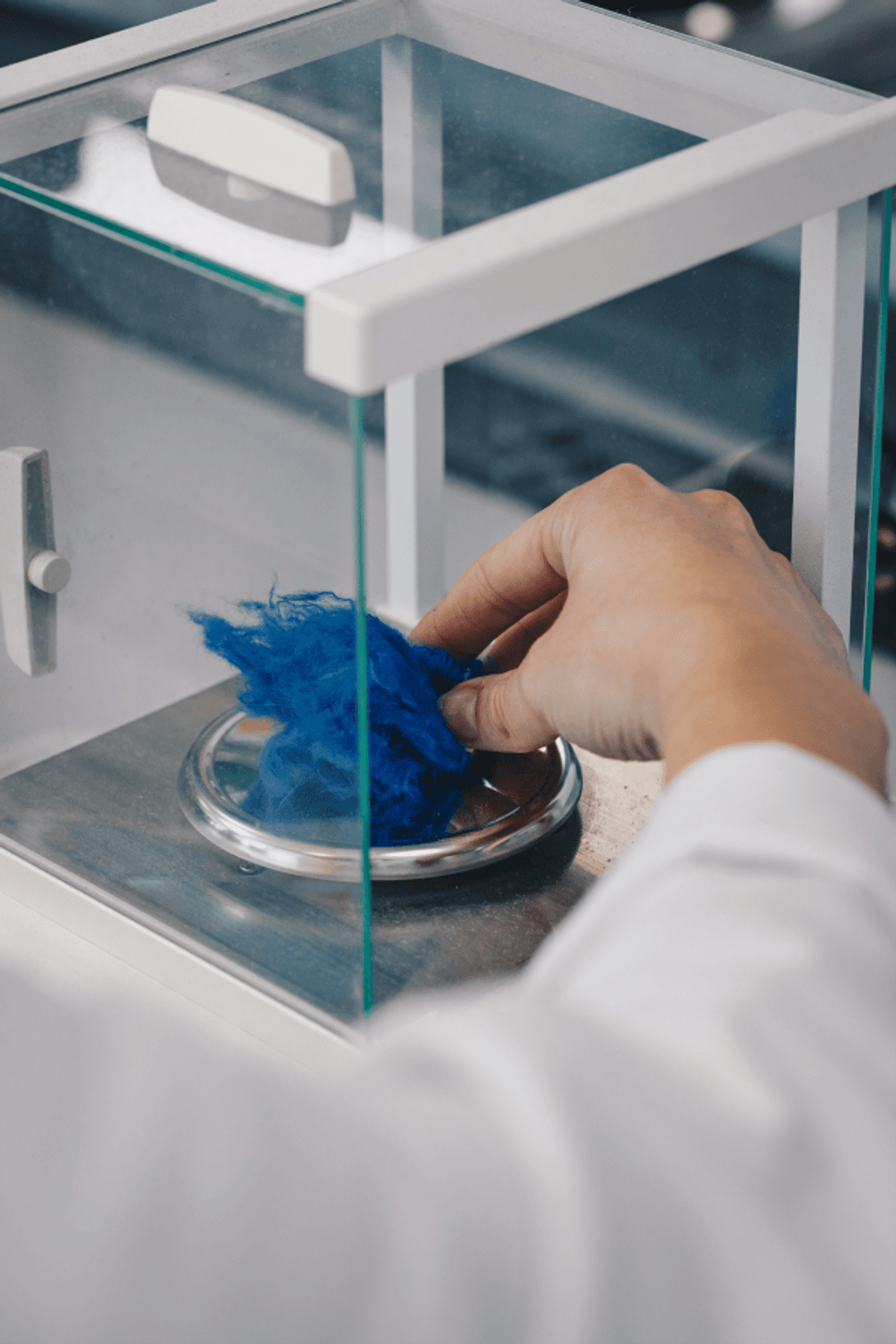

One of the things that sets RecoverTM apart is our wide color range of recycled fibers. But what goes into developing the RecoverTM swatch book? Research, testing and quality controls ensure that we can offer the highest quality of each of the industry-leading colors.

Recycling textiles is an exciting frontier that opens the door to a more sustainable future. By using existing textiles that have been previously treated and dyed, we can take advantage of the textiles’ colors to create a wide color range of recycled fibers without further dyeing and with a minimal amount of chemicals. Apart from optimizing textile waste’s available color gamut, we have also fine-tuned the recycling process to ensure the highest quality recycled fiber. Over the last 75 years, we have developed a proprietary system that not only allows us to maintain fibers’ length but also its integrity, creating low-impact fibers to meet the market’s color demands.

One of Recover’s most popular products, RColorBlend, comes in a broad spectrum of ready-made colors. But how exactly does it work?

RecoverTM has carefully-calculated the composition of our RColorBlend products to offer the highest quality and color diversity. This product line is currently available in two blends:

Depending on the client’s final goal – including color, sustainability and scale – we develop the fiber’s unique ‘recipe’. Here’s a look at our process:

This process allows us to meet the industry’s demands while continuing to salvage incoming textile waste, closing the loop with a colorful range of recycled fibers.