All You Need to Know About Textile Spinning

Site map

Growing textile consumption and waste volumes in Europe are a global problem. Europe generates 7 - 7.5 million tons textile waste per year, of which only 30 - 35% [1] is collected. Today, incineration and landfills are its primary end destinations [2] whereas less than 1 percent of textile waste is fiber-to-fiber recycled.

“Fiber-to-fiber recycling at scale can help address Europe’s waste problem by turning waste into value” states a recent report published by McKinsey. Their analysis indicates that fiber-to-fiber recycling could reach 18 to 26 percent of gross textile waste in 2030. To capture this opportunity, they ask to start expanding the required infrastructure for collection, sorting, and closed-loop recycling by today. This further amplifies the ambitious goals of the ReHubs initiative that were announced during a press conference at Techtextil 2022 in Frankfurt on June 22nd.

ReHubs aims to bring together key European and global players to solve the European textile waste problem

by transforming “waste” into a resource, and to boost closed loop business models at scale. The press release explains the initiative’s plan to pursue fiber-to-fiber recycling for 2.5 million tonnes of textile waste by 2030. To this end, the ReHubs will set and monitor the European textile recycling roadmap and will orchestrate collaboration and trigger projects.

As a business council member, Recover™ has supported and contributed to the work of ReHubs in the past 1.5 year together with other companies including Lenzing, Texaid, Inditex, Decathlon, and Soex engaged.

At the press conference during Techtextil, ReHubs initiator, Euratex, highlighted that the value chain for textile recycling is not yet mature. Waste is expected to increase in 2030 up to 8.5-9 million tons and with the implementation of EU regulation on separate textile-waste collection by 2025, rates for the collection of post-consumer household waste could increase to 50 percent by 2030. For that reason, closing the loop requires building a new circular value chain in Europe that would need significant additional capacity of around 150 – 250 new facilities.

The McKinsey’s report “Scaling textile recycling in Europe—turning waste into value”, estimates the capital expenditure investments needed to reach this scale would be in the range of €6 billion to €7 billion by 2030. Nevertheless, the analysis also indicates that the industry could become a profitable industry with a €1.5 billion to €2.2 billion profit pool. Beyond the direct economic benefits, scaling textile recycling unlocks several environmental and social benefits. For example, about 15,000 new jobs could be created and CO2 emissions could be reduced by approximately 4 million tons.

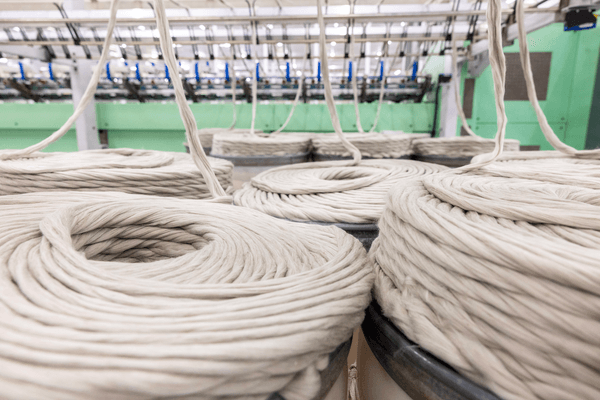

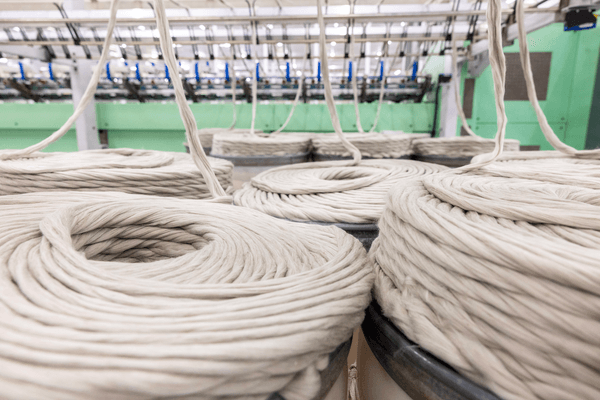

Specifically, the report identifies “mechanical recycling technologies” as the most CO2 emission-friendly, with a reduction potential of 60 to 90 percent across all fiber types on spun fiber levels. In addition, some mechanically recycled fibers, including Recover™ RColorBlend fibers, avoid emission-intense, post-material processing, which saves more CO2 emissions. Recover™ RColorBlend fibers for example already have a color. They are a blend of recycled cotton from textile waste and low impact dyed recycled polyester, removing the need for garment dye in downstream manufacturing.

As next steps for textile circularity, the report highlights actions required to capture the opportunity at stake. “Real collaboration” is identified as one of the main ingredients for success. Business leaders across the value chain, investors, and leaders of public institutions would need to come together in an unprecedented way to engage in a highly operational joint effort to overcome the barriers to scale. In addition to this, public-sector push, investments and transition funding are also identified as major actions.

In this regard, the ReHubs is working on four initial projects stretching across the circular value chain from textile waste to final products: 1) Transform textile waste into feedstock; 2) Increase the adoption of mechanically recycled fibers in the value chain; 3) Technical challenges for thermo-mechanical textiles recycling; 4) Create capsule collection with post-consumer recycled products.

As a leading mechanical recycler, Recover™ is committed to help build the systems, standards and physical capacity that is required to close the loop for textiles in Europe. Currently, Recover’s main raw material is post-Industrial waste, but the aim of the company is to increase significantly the amount of post-consumer feedstock, especially in Europe, where a lot of this waste will become available.

-----------------------------------------------------------------------

[1] ReHubs. Press meeting document (22nd June 2022, Frankfurt)