Our quality promise

Our Quality Promise

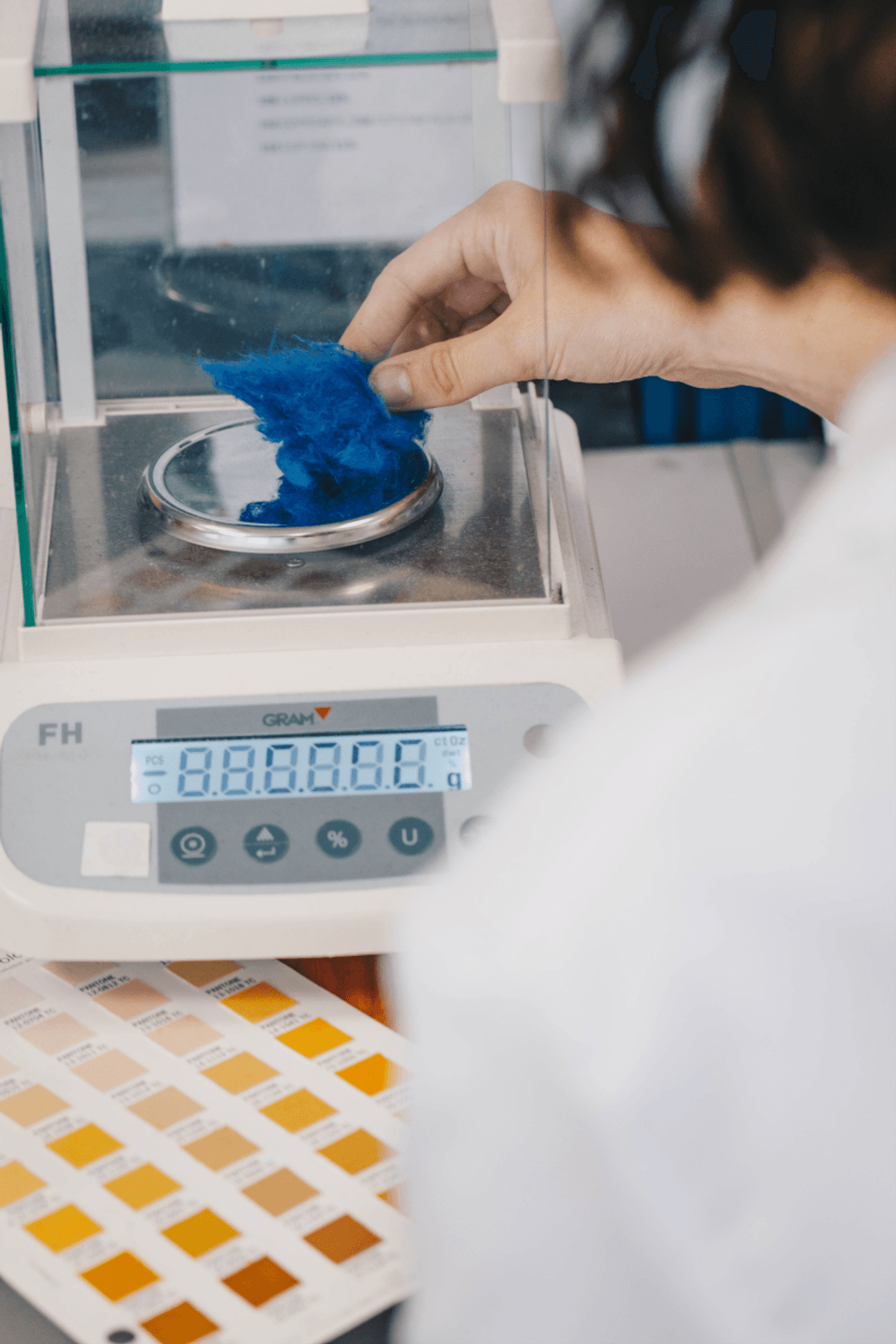

Recover™ strives to guarantee the highest standards of quality, sustainability and safety for our products, processes, premises and people. Our team oversees the implementation of our rigorous quality management system and quality policy, to guarantee a reliable product, at scale, by systemic quality control and continuous improvements.

A truly sustainable product, at the highest quality.

Our expert team of 22 people across our dedicated Recover™ laboratories in Spain and Bangladesh ensure our quality promise. Through decades of experience, strict quality controls and reliable fiber results, our quality has greatly evolved to produce recycled cotton fiber with:

• Reduced short fiber content.

• Reduced amount of unshredded material as neps and yarns

• Applications for both ring spinning and open-end.

The highest standards

Recover´s Quality Management System, based on the International Standard ISO 9001:2015, was implemented in our manufacturing hubs and headquarters. The focus of our Quality Management System is customer satisfaction as well as the optimization of processes and continual improvement. Furthermore, the ISO 9001 aids a proactive and preventive culture by identifying and analyzing the risks and opportunities that are relevant to the company, or those that may affect the conformity of products and services enhancing the ability to increase customer satisfaction.

We have also implemented our own Chemical Management System (CMS) with the aim of removing hazardous chemicals from the value chain and focusing on safety, traceability, transparency and continuous improvement. This is also reflected in our Chemicals Policy. Chemical management requires a systematic approach throughout all production stages, including the input, chemical usage and handling in facility areas, and the output in our products. The CMS is also aligned with industry standards that are used to monitor output chemicals that might be placed in the value chain and, eventually, reach consumers and or the environment.

As a certification of the robust quality controls carried out, for every batch of Recover™ recycled cotton produced a Fiber Analysis Report is created with all the results obtained.

We create a Quality Assurance Report for all batches of Recover™ recycled cotton fiber produced in Bangladesh, Spain and Pakistan.

Supply Chain Support

Our Supply Chain Quality team works on the ground with the textile sorters to align on quality and assure the raw material specifications.

Out Tech Support team works with partners further down the supply chain to guide them during the development of yarn and fabrics, assuring best practices to obtain the best possible final product.